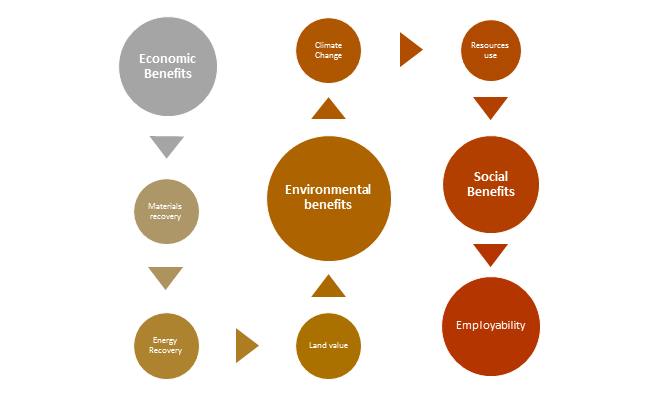

Landfills have always been considered as the main practice of the waste disposal for the minimum costs ensured [1]. However, this practice implicates local pollution, methane emissions, as well as limitations as regard of the urban development [2]. These concerns resulted into the development of the new concept of “Enhanced Landfill Mining” (ELFM) proposed by Jones et al. “This process involves the excavation and processing of waste from closed landfill sites or the completed sections of operational landfill sites”. It represents “the integrated valorisation of landfilled waste streams as both materials (Waste-to-Material) and energy (Waste-to-Energy), using innovative transformation technologies and respecting the most stringent social and ecological criteria” [3]. The following figure illustrates the potential benefits associated to this concept such as:

Economic benefits:

- Material and energy recovery;

- Recovery of landfill space, reduction of its surface, and remediation of contaminated spaces (>2800 - 6000 km 2, nature-urban-industrial purposes) [3].

- Reduced maintenance costs (€ 0, 1-1 trillion if ELFM concept is used for all EU-landfills) [3].

Social benefit:

- Employment: direct (construction and recycling sector), indirect (goods and services purchase of the recycle industry) or inducted (direct and indirect employees expenditure in other economic activities). For instance, with regard to the “Closing the Circle” project undertaken in Houthalen-Helchteren landfill in Belgium, between 600 and 800 people were employed within a year [5]. Up to 240.000-800.000 new jobs in EU-27 for full implementation of ELFM [3].

Environmental benefits:

- Mitigation of climate change by the reduction of greenhouse gas emissions.

- Reduction of pressure in natural resources.

- Stimulation of the use of secondary raw materials.

On the other hand the potential drawbacks are pointed below [6]:

- Hazardous waste: managing costs of hazardous materials may be considerably high;

- Controlling releases of landfill gases and odors;

- Stability and safety control;

- Equipment lifespan.

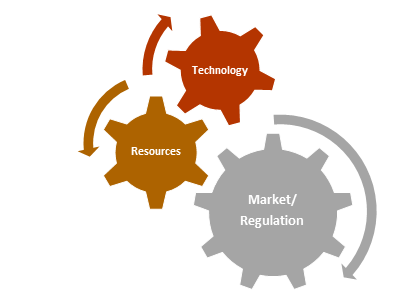

Furthermore, the figure illustrated below shoes the several factors that may affect the potential advantages of the ELFM [4]:

The quantity and quality of resources deposited in landfills: the materials come from different geographical areas and they could depend upon the variation of the consumption patterns as well as the degradation degree.

The technologic capacity available: for instance, a stationary plant extraction process has a global environmental impact of emissions more favorable than processes by mobile plants because of the higher percentage of materials per unit of energy supplied. Moreover, being the analysis of waste composition still manual, it is difficult to analyse a representative amounts of solid waste material due to the high costs associated. Peter T. J., (2015), argued that a set of innovative technologies needs to be developed in order to effectively turn waste into valuable products. An ongoing research characterized by X-Ray transmission has been proposed in order to overcome this limitation (Geurts, R. et al) [7].

The price of certain resources which depends upon their demand on the market: it has been affirmed that the increase in the price of virgin metals could entail an increase in the price paid for recovered materials. As a consequence the energy demand would grow and the landfill mining could become more profitable and necessary [4].

The regulation: The Landfill Directive 1999/31/EC defines the different categories of waste (municipal waste, hazardous waste, non-hazardous waste and inert waste) and it considerably improved the safety of the landfill operations in terms of environmental impact [8]. Nevertheless, there is not yet a clear strategy regarding landfills and the related potential [9].

To sum up:

- A detailed analysis of the economic viability needs to be undertaken because of the wide range of factors affecting directly or indirectly each landfill mining project proposal [2].

- “New processes are needed to upcycle waste streams into high added value products, to move from linear to circular business models as well as to valorise the ELFM concept by developing industrial consortium to bring together know how and funds” (Tielemans Y., 2015) [10].

References

- Eurostat, 2009. Waste generated and treated in Europe. Office for Official Publications of the European Communities, Luxembourg. Kollikkathara, N., Feng, H., Stern, E., 2009. A preview of waste management evolution: Special emphasis on USA. Waste Management 29, 974–985.

- Krook et al., 2012. Landfill mining: A critical review of two decades of research. Waste Management 32, 513–520).

- T. Jones et al. 2013. Enhanced Landfill Mining in view of multiple resource recovery: a critical review. Journal of Cleaner Production, 55, 45-55.

- Puig Ventosa, I., Calaf Forn, M., Jofra Sora, M., 2011. Minería urbana: extracción de recursos de los vertederos. Fundacion Mapfre. Convocatoria Ayuda a la Investigación 2011.

- Sips, K.; Kuppers, P., 2011. A journey from Cradle to Cradle. C2C network Initiatives Guide, Stafford Wadsworth.

- United States Environmental Protection Agency. 1997. Solid Waste and Emergency Response.

- Geurts, R., Maul, A.,Broos K.,,Van Loo D.,Boone M., Segers, P., Vanhees J. and Quaghebeur M. But, is it all dirt!? Advanced characterisation of ELFM material by the Characterise-to-Sort technology.

- EURELCO. 2017. Landfill Mining Overview.

- Peter T. J., (2015). First seminar about Enhanced Landfill Mining. European Parliament.

- Tielemans Y., (2015). First seminar about Enhanced Landfill Mining. European Parliament.